1969 Dodge Coronet on 2040-cars

Ocala, Florida, United States

Please message me with questions at: darrickdsswayze@ukhouse.com .

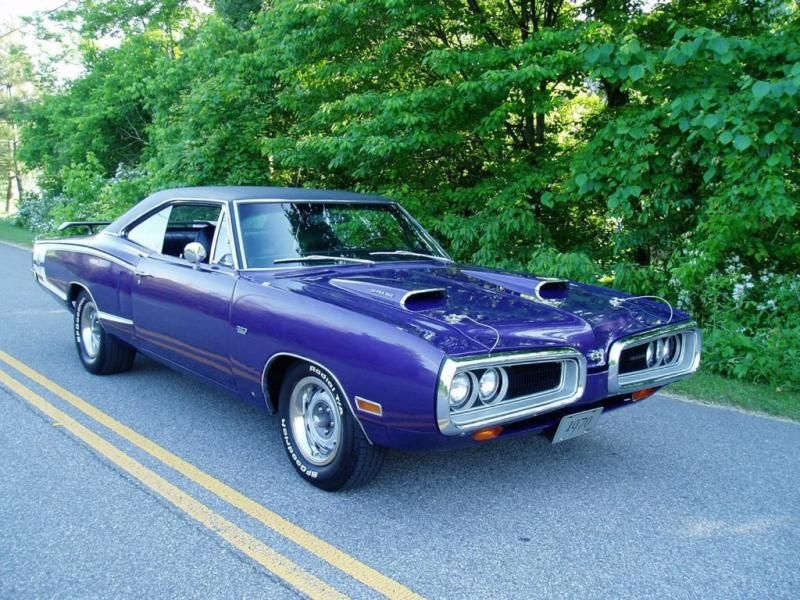

She is a REAL DEAL documented numbers matching 1969 1/2 SuperbeeA12 M Code 440-6 automatic.

Highlights include:

Superb Numbers matching 440 390hp engine with just 29,354 miles from new

One of just 661 automatic hard top produced

Superb body

Nice paint

Original throughout ( one repaint about 8 years ago and about 650 miles ago)

Super original survivor interior

Consul and bucket seat Superbee

Original rustfree floors, rockers and trunk floor

Original color and specs

Fender tag matches Vin and partial vins body numbers

Nice top

Broadcast sheet

Power steering

Power brakes

Original lift up pins

Never crashed or rusty

Drives and looks superb

Everything works

Walk around video available

Superb muffler sound

Clear title

Dodge Coronet for Sale

1968 dodge coronet rt(US $14,950.00)

1968 dodge coronet rt(US $14,950.00) 1970 dodge coronet super bee(US $14,950.00)

1970 dodge coronet super bee(US $14,950.00) 1967 dodge coronet rt 440 magnum(US $16,200.00)

1967 dodge coronet rt 440 magnum(US $16,200.00) 1969 dodge coronet super bee(US $19,500.00)

1969 dodge coronet super bee(US $19,500.00) 1970 dodge coronet super bee --(US $7,700.00)

1970 dodge coronet super bee --(US $7,700.00) 1969 dodge coronet super bee(US $14,500.00)

1969 dodge coronet super bee(US $14,500.00)

Auto Services in Florida

Workman Service Center ★★★★★

Wolf Towing Corp. ★★★★★

Wilcox & Son Automotive, LLC ★★★★★

Wheaton`s Service Center ★★★★★

Used Car Super Market ★★★★★

USA Auto Glass ★★★★★

Auto blog

New Viper 'is a possibility,' Sergio Marchionne says

Wed, Jan 13 2016It was thought the door to the future for the Dodge Viper had closed last year, but Fiat Chrysler CEO Sergio Marchionne reopened it during his press conference at the 2016 Detroit Auto Show. Marchionne said the current Viper is the only FCA product to use the ZD platform, which "doesn't make sense to me." Yet, "given the architectural development within the brand, there is a possibility that a new version of the Viper may surface." Automobile reports that the company uses a versatile, rear- and all-wheel drive Giorgio platform for Alfa Romeo and Dodge. It will support the Alfa Romeo Giulia (Alfa Romeo's larger BMW 5 Series competitor), the next-generation Dodge Challenger, Charger, and rumored Barracuda, and it could support a new generation of Viper. We're probably talking about a different kind of Viper, though, with Automobile saying, "the current car's truck-based V-10 no doubt would be scrapped along with its platform." A Viper without a V10 doesn't seem like a Viper to us, but we'll wait to see what happens. In the midst of contract negotiations for a new labor agreement between FCA and the United Auto Workers last year, it emerged that the Conner Avenue Assembly plant that builds the Viper hadn't been given any new product after the end of Viper build-out in 2017. That led most to reason that the current Viper would be the end of the 25-year run of America's hairiest sports car. How long we'll be waiting is unknown. Marchionne had no timetable and admitted that a future Viper might not appear on the heels of the current one. With a renewed commitment to being debt-free by 2018, FCA is likely more focused on getting Alfa Romeo running properly and cranking out the volume variants for the Giorgio platform first. Related Video: Featured Gallery 2014 SRT Viper GTS: Review View 36 Photos News Source: Automobile via World Car FansImage Credit: Copyright 2015 Drew Phillips / AOL Detroit Auto Show Dodge Coupe Performance Sergio Marchionne FCA conner avenue assembly plant

'Baby Driver' is a car chase movie set to music

Mon, Mar 13 2017The Fate of the Furious is certainly the 6,000-pound SUV in the garage of automotive movies, but that doesn't mean gearheads are starved for options. The upcoming film Baby Driver looks to be a winner for car guys, featuring exciting chases with cars including a "hawk-eye" Impreza WRX, a Dodge Challenger, and a 1980s Chevy Caprice. The movie is written and directed by Edgar Wright, whom you may know as the man behind movies such as Sean of the Dead, Hot Fuzz, and Scott Pilgrim vs. The World. And based on the two trailers released so far, seen above and below, it's about a young man by the name of Baby, who is a getaway driver for criminals. He's apparently the best in the business, and the secret to his success is the music he listens to while he's driving. He also wants out, but his boss, played by Kevin Spacey, has no intention of letting him go. Spacey is one of a number of major stars in the film, including Jamie Foxx and John Hamm. The driving action shown in the trailers definitely looks entertaining. The WRX is seen doing an array of drifts and J-turns. There is some driving precision on display here that wouldn't be out of place in a Gymkhana video. And it looks like Wright's attention to detail in his shots and transitions, as well as some solid comedy relief, are all going to be present. The film comes out this August. Related Video: News Source: Sony Pictures Entertainment / YouTube via Road & TrackImage Credit: Sony Pictures Entertainment / YouTube TV/Movies Chevrolet Dodge Subaru Videos baby driver

2019 Dodge Charger SRT Hellcat gets a Challenger-style intake in the grille

Wed, May 9 2018Yesterday, we discovered that Dodge was working on some sort of update to the nose of the Charger Hellcat. Today, Dodge revealed what the change is. It's a new grille with an intake outlet. Basically, the 2019 Dodge Charger SRT Hellcat will have the equivalent of the Challenger Hellcat's intake headlight. But since there isn't a convenient light to cut a hole in, Dodge just put a bigger hole in the grille next to the driver's side headlight. Presumably it leads right to the intake box like the intake on the Challenger. Close examination also reveals that the mesh has changed, as well. The 2019 model's grille has a bit more detail, and the openings are more round than the current model. No other aspects of the updated model have been revealed, but those details should come when the car is fully revealed this summer, along with the new Challenger. Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Image Credit: Dodge Dodge Performance Videos Sedan dodge charger srt hellcat