2012 Chevrolet Volt Electric/hybrid~1 Owner~no Accidents~compare & Save!! on 2040-cars

Sanford, North Carolina, United States

Chevrolet Volt for Sale

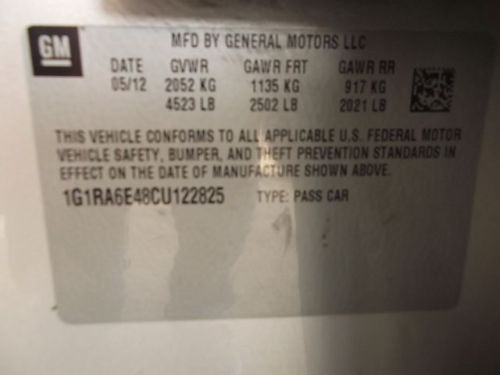

2012 chevrolet volt base hatchback 4-door 1.4l(US $16,900.00)

2012 chevrolet volt base hatchback 4-door 1.4l(US $16,900.00) 5dr hb low miles 4 dr hatchback automatic engine, range extender, 1.4l internal(US $27,991.00)

5dr hb low miles 4 dr hatchback automatic engine, range extender, 1.4l internal(US $27,991.00) Clean autocheck 35 miles electric 300+ miles gasoline range mytouch alloys xenon(US $19,980.00)

Clean autocheck 35 miles electric 300+ miles gasoline range mytouch alloys xenon(US $19,980.00) Beautiful..... low miles....low reserve

Beautiful..... low miles....low reserve 8 miles 2014 new automatic front wheel drive hatchback premium onstar tx black(US $38,506.00)

8 miles 2014 new automatic front wheel drive hatchback premium onstar tx black(US $38,506.00) 7 miles 2014 new automatic hatchback onstar white diamond gps loaded plug in tx(US $39,500.00)

7 miles 2014 new automatic hatchback onstar white diamond gps loaded plug in tx(US $39,500.00)

Auto Services in North Carolina

Wilburn Auto Body Shop-Mooresville ★★★★★

Westover Lawn Mower Service ★★★★★

Truck Alterations ★★★★★

Troy Auto Sales ★★★★★

Thee Car Lot ★★★★★

T&E Tires and Service ★★★★★

Auto blog

GM natural gas-powered vans recalled due to possible leak

Wed, Sep 24 2014General Motors is recalling almost 3,200 of its compressed-natural-gas powered utility vans because of possible leaks. GM and the National Highway Traffic Safety Administration (NHTSA) released a notice last week saying that 3,196 Chevrolet Express and GMC Savana CNG vans are on recall, though no accidents have been reported due to the possible issue. The recall is specifically for vans for model years ranging from 2011 to 2014. The recall stems from a potential leak from the compressed natural gas high-pressure regulator, and such a leak could cause a fire or explosion. GM will replace the vehicles' high-pressure regulator in order to fix the problem, will do it free of charge and is instructing owners to contact Chevrolet or GMC customer service to arrange for the parts replacement. Utility vehicle makers like General Motors have pushed for fleet sales of CNG-powered vans and trucks for the past few years and have touted them for their cheaper refueling costs relative to standard gasoline, not to mention the fact that natural gas can be readily sourced from throughout North America (thanks, fracking). According to CNGPrices.com, compressed natural gas sells for about $2.22 a gallon, on average, while the AAA is pegging the average price of gas at $3.34 a gallon. NHTSA has posted information on the recall here. Featured Gallery News Source: NHTSA via Reuters Green Chevrolet GM GMC Natural Gas Vehicles CNG gmc savana

Cruze Diesel Road Trip reveals the good and bad, but no ugly

Tue, Mar 31 2015Most of us have strong opinions on diesel-powered cars based on our perceptions of and experience with them. I used to thoroughly dislike oil burners for their noise, smoke and lackluster performance, and the fact that they ran on greasy, smelly stuff that was more expensive than gasoline, could be hard to find and was nasty to get on your hands when refueling. Those negatives, for me, trumped diesel's major positives of big torque for strong acceleration and better fuel economy. Are any of those knocks on diesel still valid today? I'm not talking semis, which continue to annoy me when their operators for some reason almost never shut them down. At any busy truck stop, the air seems always filled with the sound – and sometimes smell – of dozens of big-rig diesels idling endlessly and mindlessly. Or diesel heavy-duty pickups. Those muscular workhorses are far more refined than they once were and burn much less fuel than their gasoline counterparts. But good luck arriving home late at night, or departing early morning, without waking your housemates and neighbors with their clattery racket. No, I'm talking diesel-powered passenger cars, which account for more than half the market in Europe (diesel fuel is cheaper there) yet still barely bump the sales charts in North America. Diesel fuel remains more expensive here, too few stations carry it, and too many Americans remember when diesel cars were noisy, smelly slugs. Also, US emissions requirements make them substantially more expensive to certify, and therefore to buy. But put aside (if you can) higher vehicle purchase and fuel prices, and today's diesel cars can be delightful to drive while delivering much better fuel efficiency than gas-powered versions. So far in the US, all except Chevrolet's compact Cruze Diesel come from German brands, and all are amazingly quiet, visually clean (no smoke) and can be torquey-fun to drive. When a GM Powertrain engineering team set out to modify a tried-and-true GM of Europe turbodiesel four for North American Chevy Cruze compacts, says assistant chief engineer Mike Siegrist, it had a clear target in mind: the Volkswagen Jetta TDI 2.0-liter diesel. And they'll tell you that they beat it in nearly every way. "I believe we have a superior product," he says. "It's powerful, efficient and clean, and it will change perceptions of what a diesel car can be." The 2.0L Cruze turbodiesel pumps out 151 SAE certified horses and 264 pound-feet of torque (at just 2,000 rpm) vs.

Chevy Traverse, Hyundai Santa Fe revealed; Buick Envista, BMW M4 CSL driven | Autoblog Podcast #790

Fri, Jul 21 2023In this episode of the Autoblog Podcast, Editor-in-Chief Greg Migliore is joined by Senior Editor John Beltz Snyder. After some banter, including the discussion of an excellent tomato sauce recipe, they get into car reviews. Greg has been driving the Mercedes-AMG GLE 53, while John has been testing the BMW M4 CSL and Buick's new Envista crossover. There's lots of interesting news this week. Chevy revealed the 2024 Traverse with new looks, a new engine and on off-road(ish) trim. Hyundai gave us a glimpse at the wild styling of the next Santa Fe. Dodge might bring back the Stealth nameplate as an SUV, and that has implications for the Durango as well. Ford, after repeatedly raising prices, has turned around and significantly discounted the F-150 Lightning across all trims. The first Tesla Cybertruck has rolled off the line as a pre-production prototype. Finally, we reach in to the mailbag and help a listener decide what to do with cars for himself and his kids in this week's Spend My Money segment. Send us your questions for the Mailbag and Spend My Money at: Podcast@Autoblog.com. Autoblog Podcast #790 Get The Podcast Apple Podcasts – Subscribe to the Autoblog Podcast in iTunes Spotify – Subscribe to the Autoblog Podcast on Spotify RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Rundown Cars we're driving 2023 Mercedes-AMG GLE 53 2023 BMW M4 CSL 2024 Buick Envista 2024 Chevrolet Traverse gets rugged looks, new turbo engine, Z71 trim 2024 Hyundai Santa Fe revealed with a radical redesign Dodge Stealth coming with new platform, looks, and powertrains in a year (Bonus reading: check out Dodge Stealth listings) Ford F-150 Lightning gets significant price cut across the full range First Tesla Cybertruck pre-production prototype comes off the line Spend My Money Feedback Email – Podcast@Autoblog.com Review the show on Apple Podcasts Autoblog is now live on your smart speakers and voice assistants with the audio Autoblog Daily Digest. Say “Hey Google, play the news from Autoblog” or "Alexa, open Autoblog" to get your favorite car website in audio form every day. A narrator will take you through the biggest stories or break down one of our comprehensive test drives. Related video: Green Podcasts BMW Buick Chevrolet Dodge Ford GM Hyundai Mercedes-Benz Tesla Truck Crossover SUV Electric Future Vehicles Luxury Off-Road Vehicles Performance