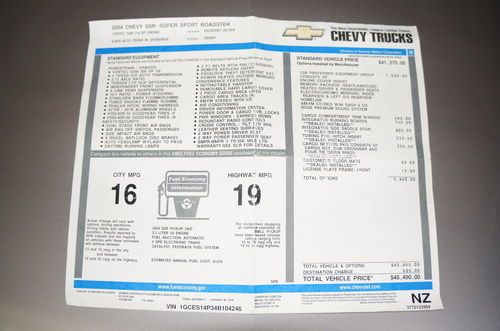

2004 Chevrolet Ssr Convertible 2-door 5.3l Great Shape!!! Low Miles!!! on 2040-cars

Fairmont, West Virginia, United States

Body Type:Convertible

Vehicle Title:Clear

Engine:5.3L 325Cu. In. V8 GAS OHV Naturally Aspirated

Fuel Type:GAS

For Sale By:Private Seller

Make: Chevrolet

Model: SSR

Warranty: Vehicle does NOT have an existing warranty

Trim: Base Convertible 2-Door

Options: Bose stereo, Power retractible hard top, Saddle Bags, Carpeted bed w/ wood trim, Running Boards, Leather Seats, CD Player, Convertible

Drive Type: RWD

Safety Features: Anti-Lock Brakes, Driver Airbag, Passenger Airbag

Mileage: 14,858

Power Options: Power retractable hard-top, Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Exterior Color: Ricochet Silver

Interior Color: Ebony

Number of Cylinders: 8

Chevrolet SSR for Sale

2006 ssr 6 speed manual 14k miles ls2 wow convertible

2006 ssr 6 speed manual 14k miles ls2 wow convertible Chevrolet ssr loaded 5k miles like new step boards htd seats bed trim 2004(US $29,500.00)

Chevrolet ssr loaded 5k miles like new step boards htd seats bed trim 2004(US $29,500.00) Chevrolet ssr(US $30,000.00)

Chevrolet ssr(US $30,000.00) One of a kind magna super charged, 6.0 ls2 motor, 525 hp, original tires(US $33,500.00)

One of a kind magna super charged, 6.0 ls2 motor, 525 hp, original tires(US $33,500.00) 2005 chevrolet ssr base convertible 2-door 6.0l

2005 chevrolet ssr base convertible 2-door 6.0l 2005 chevy ssr indy edition 1 of 50(US $23,500.00)

2005 chevy ssr indy edition 1 of 50(US $23,500.00)

Auto Services in West Virginia

Zim`s Tire & Auto Svc ★★★★★

Taylor Auto Body ★★★★★

Ramey Save A Lot ★★★★★

Price Brothers Garage ★★★★★

Outcast Bug & Buggy Shop ★★★★★

Lee`s Auto & Small Engine Repair ★★★★★

Auto blog

2016 Chevrolet Spark lights up New York

Thu, Apr 2 2015The little Spark has been somewhat of a surprising entry in the modern Chevy lineup in the US. Given its diminutive stature, you might have expected the slightly larger Sonic to cannibalize the tiny sibling's sales, but that hasn't happened. The Bowtie moved 39,159 Sparks in the US in 2014, a 14.7 percent boost from the previous year. Now at the 2015 New York Auto Show, the latest generation is being unveiled with a new engine and much improved styling. Replacing the current 1.2-liter four-cylinder is an all-aluminum 1.4-liter unit making 98 horsepower. That still doesn't sound like much, but it's 16 percent more than the 2015 Spark. The new mill can be connected to either a five-speed manual or a continuously variable transmission with which Chevy estimates 40 miles per gallon highway fuel economy. The 2016 Spark also gets a longer wheelbase and 1.6-inch lower overall height. Combined with more elliptical headlights at the front, the changes make for a somewhat more sleek appearance than the current, boxy model. The platform underneath is more rigid as well, and Chevy claims the latest underpinnings mean better handling and lower NHV levels inside. The little hatch isn't growing up too much, though, and gets a trio of new colors that sound like jellybean flavors: Toasted Marshmallow, Kalamata and Splash. Chevy is packing the interior with better quality materials and improved tech. Chevy's latest seven-inch MyLink system sits in the center stack with a capacitive touchscreen, and it now comes with a physical volume control and other buttons for easier use. All models also get a rearview camera, and a LCD instrument cluster remains in front of the driver. The available suite of safety systems includes Forward Collision Alert, Lane Departure Warning and Side Blind Spot Alert. The 2016 Spark goes on sale in the US in the fourth quarter of 2015 and is produced in South Korea. Expect a gallery showing off all its new styling from the New York show floor soon.

Corvette Stingray gets optional Z06 components

Thu, Nov 5 2015If you've got a Corvette Stingray in the garage and have been tempted by some of the upgrades incorporated into the Z06, but can't quite bring yourself to trade up, Chevy has got some good news for you. The Bowtie brand has announced a series of performance parts derived from those in the Z06, but applicable to the base Stingray. The list of parts includes new cooling elements, prop shafts, brakes, suspension components, and underbody braces. They can all be fitted to Stingray models with or without the Z51 performance kit, and promise to raise the Corvette's game if not quite to Z06 levels, then closer to them. And for Z06 owners interested in gaining a bit more advantage, Chevy is offering a new Level 3 aero kit as well. The parts were demonstrated on upgraded 'Vettes at the Ron Fellows driving school at Spring Mountain. The school is also serving as technical partner and the track as the location for a new spec racing series built around the C7 Corvette. Dubbed the Michelin Corvette Challenge, the calendar is composed of fifteen half-hour races held in pairs over eight weekends, all on the six-mile circuit near Las Vegas. The cars to be used in the series will be close to showroom stock and feature many of the new Z06-derived upgrades, with Michelin racing slicks for dry weather and Pilot Super Sport tires in the wet. Perhaps most compelling of all will be the payment plan that will allow participating amateur racers to pay in installments across the season and take home their Corvette after the season's conclusion in December. New Z06 Parts Enhance Corvette Stingray Performance Broad range of chassis, suspension and aero components enhance capability 2015-11-02 PAHRUMP, Nev. – Chevrolet today and drivers from the Ron Fellows Corvette high-performance driving school at the Spring Mountain track demonstrated Stingray models enhanced with components from a new lineup of Z06-based performance parts. They're designed for 2014+ Stingray models, including Z51-equipped cars. "We've selected specific components from the Corvette Z06 and engineered them to fit the award-winning Stingray," said Jim Campbell, Chevrolet U.S. vice president of Performance Vehicles and Motorsports. "These Z06 parts enhance the handling, braking, cooling and downforce performance of the Stingray." Ron Fellows, champion Corvette Racing driver, collaborated with Chevrolet Performance engineers on the all-new portfolio.

2021 Chevy Silverado, GMC Sierra fuel economy to go down due to global chip shortage

Mon, Mar 15 2021Production of the 2021 Chevy Silverado and 2021 GMC Sierra is continuing, but the global semiconductor chip shortage is resulting in a mid-year change. Or rather, an omission. Basically, the availability of cylinder deactivation for the 5.3-liter V8 will be significantly reduced, resulting in a reduction of 1 mpg combined for affected models. This applies whether that engine has the six- or eight-speed automatic, as well as to both the regular Active Fuel Management and the more advanced Dynamic Fuel Management cylinder deactivation systems. DFM does remain with the pairing of 5.3-liter V8 and 10-speed automatic that comes standard on the LT Trail Boss and High Country. "Due to the micro controller shortage, the components that control AFM/DFM in the engine control module (ECM) have been removed," GM spokesperson Michelle Malcho told Autoblog. She also indicated that the engines will still have the AFM/DFM hardware in place, but that GM will not allow activation of the systems in the future with an ECM change. Malcho also confirmed to Autoblog that the Silverado and Sierra's other engines will continue to have AFM and DFM, including the 2.7-liter turbo inline-four, 4.3-liter V6 and 6.2-liter V8. In an earlier statement to Reuters, she declined to say the volume of vehicles affected. "By taking this measure, we are better able to meet the strong customer and dealer demand for our full-size trucks as the industry continues to rebound and strengthen," Malcho wrote Reuters in an email. The change runs through the 2021 model year, she said. Malcho told Reuters it would not have a major impact on the Detroit automaker's U.S. corporate average fuel economy (CAFE) numbers. "We routinely monitor our fleet for compliance in the U.S. and Canada, and we balance our portfolio in a way that enables us to manage unforeseeable circumstances like this without compromising our overall (greenhouse gas) and fuel economy compliance," she said. GM's fleetwide fuel economy in the 2018 model year was 22.5 miles per gallon and was projected to rise to 22.8 mpg for 2019, according to a report by the Environmental Protection Agency. To meet federal CAFE requirements, automakers like GM often use credits from either earlier years where they faced less stringent rules and performed better than the requirements or buy credits from other automakers. GM said last month the chip shortage could shave up to $2 billion from this year's earnings.