Chevy Corvette { One Owner} on 2040-cars

Phoenix, Arizona, United States

Engine:6.0L 5967CC 364Cu. In. V8 GAS OHV Naturally Aspirated

For Sale By:Dealer

Body Type:Convertible

Transmission:Automatic

Fuel Type:GAS

Make: Chevrolet

Options: Leather, Compact Disc

Model: Corvette

Safety Features: Anti-Lock Brakes

Trim: Base Convertible 2-Door

Power Options: Air Conditioning, Cruise Control, Power Windows

Drive Type: RWD

Doors: 2

Mileage: 18,859

Engine Description: 6.0L V8 SFI (400 HP [298.

Sub Model: 2dr Conv

Number of Doors: 2

Exterior Color: Red

Interior Color: Tan

Number of Cylinders: 8

Warranty: Vehicle has an existing warranty

Chevrolet Corvette for Sale

2000 immaculate corvette, targa top, champagne/gold color with 65k miles(US $18,500.00)

2000 immaculate corvette, targa top, champagne/gold color with 65k miles(US $18,500.00) 1990 chevrolet corvette base convertible 2-door 5.7l

1990 chevrolet corvette base convertible 2-door 5.7l 2009 corvette zr1 cyber grey low miles like new condition(US $78,900.00)

2009 corvette zr1 cyber grey low miles like new condition(US $78,900.00) 2012 6.2l auto carbon_flash(US $48,900.00)

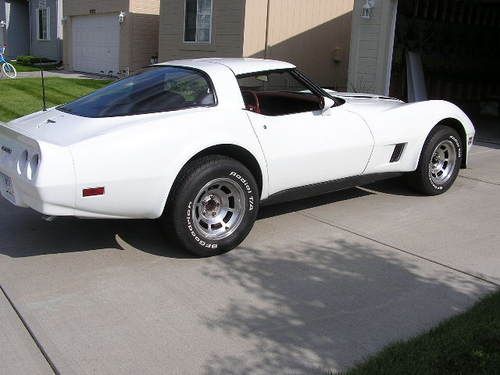

2012 6.2l auto carbon_flash(US $48,900.00) 1981 corvette ls1 engine

1981 corvette ls1 engine Beautiful 2006 corvette convertible z51 3lt package, le mans blue, black top(US $34,900.00)

Beautiful 2006 corvette convertible z51 3lt package, le mans blue, black top(US $34,900.00)

Auto Services in Arizona

Vince`s Automotive Repair ★★★★★

Ultimate Imports ★★★★★

Tire & Auto Service Center ★★★★★

The Ding Doctor ★★★★★

Team Ramco ★★★★★

Stockton Hill Tire ★★★★★

Auto blog

GM reintroduces Tripower name in the worst way possible

Wed, Aug 1 2018The story of General Motors' use of the Tripower moniker begins way back in 1957, when Semon E. "Bunkie" Knudsen, then General Manager of GM's Pontiac division, directed his engineers to inject more performance into his brand's line of V8-powered automobiles. Fuel injection was an option, but hot rodders flocked instead to Tri-Power (marketed way back when with a hyphen), which grafted a trio of two-barrel Rochester carburetors onto a single intake manifold. A legend was born. And that legend was born of performance. At idle and when full power wasn't required, Pontiac's Tri-Power system used just the middle carburetor, which helped make the setup easier to tune. Depending on the year and model, either a vacuum system or a mechanical linkage opened up the two outer carbs, thereby switching from two barrels to six, and allowing the engine to take in more fuel and air. And it was an easy marketing win – six barrels is better than four barrels, right? Because performance! So, when news filtered in that GM has resurrected the Tripower name, those of us who grew up attending classic car shows and wrenching on old Pontiacs did a double-take. And then we all collectively sighed. Turns out that today's Tripower refers to a trio of fuel-saving measures that include cylinder deactivation, active thermal management, and intake valve lift control, according to Automotive News. And, at least for now, it applies to GM's line of fullsize trucks powered by a 2.7-liter turbocharged four-cylinder engine. We're all for saving fuel whenever possible. And we have zero say in how any automaker chooses to market its products and technologies. But, we'll offer our two cents anyway: Relaunching a storied name from the past is fine. Relaunching a storied name from the past while completely overlooking the reasons the name got famous in the first place is only going to irritate the people who remember the name in the first place. Couldn't they just call this new technology package something else? Related Video: News Source: Automotive NewsImage Credit: Getty Green Marketing/Advertising Chevrolet GM Pontiac Automotive History Truck chevrolet silverado

Meet the mother-daughter team that's worked on almost every Chevy Volt

Sun, May 11 2014It's Mother's Day, and we're soft enough we love our mothers enough to share a new video from General Motors with you. In it, we meet Monique Watson (left) and Evetta Osbourne, a mother-daughter team that works at the Detroit-Hamtramck Assembly where GM makes the Chevy Volt (along with all of GM's other plug-in hybrids: the Opel Ampera, Holden Volt and Cadillac ELR). The two work side-by-side and have installed the lithium-ion battery pack on almost all of those vehicles - nearly 80,000 of them - since GM started making the pre-production Volts in 2009. In a prepared statement, Watson said that she likes working next to her mom, day in and day out, and they the two are totally in sync when it comes to putting the 400-pound, 16.5-kWh packs into the vehicle undersides. They two can also share stories throughout the day, and Watson said, "The arrangement has absolutely improved our relationship." Osborne started working at Detroit-Hamtramck in 1999, Watson since 2006. If you're driving a Volt today, you probably have them to thank for doing a bit of the work putting your car together. See a short video of them in action below. It's Always Mother's Day for Detroit-Hamtramck Duo Mother, daughter install lithium-ion battery pack in nearly all GM electric vehicles 2014-05-08 DETROIT – For Detroit resident Evetta Osborne, every day is Mother's Day. That's because she literally works side by side with her daughter, Monique Watson, at General Motors' Detroit-Hamtramck assembly plant. They have installed the lithium-ion battery pack on nearly every Chevrolet Volt, Opel Ampera, Holden Volt, and Cadillac ELR since production began. In fact, apart from vacation days and an occasional sick day, the mother-daughter duo has installed almost every battery pack since the Volt was in pre-production in 2009. The ELR launched earlier this year. All told – including Ampera – that's more than 80,000 electric vehicles. "We're a good team and our relationship is secondary when it comes to performing our jobs – but it's great to work alongside my daughter, said Osborne, a mother of five. Because the battery packs weigh more than 400 pounds each, automatic guided vehicles – robotic carts that use sensors to follow a path through the plant – deliver them just as the vehicle body structures glide into position overhead. The carts then lift the T-shaped packs, and Osborne and Watson guide them into the chassis and secure each one with 24 fasteners.

2015 Chevy Spark will have lighter, smaller battery

Thu, May 15 2014As General Motors gets ready to release the 2015 Chevy Spark EV, it is retooling the Brownstown Battery Assembly to build a new battery system for the chirpy little electric car. The new Spark will lose a few pounds and kWh from its lithium-ion pack, but it will keep all of it's performance specs. The current Spark EV uses a 21-kWh lithium-ion battery pack with bits made by A123 Systems (known as B456 Systems during bankruptcy). For the 2015 model, GM is going to build a 19-kWh battery system in-house that will use 192 LG Chem cells. Losing a bit of energy capacity means that the battery system for the 2015 Spark EV will be 86 pounds lighter but it will keep the EPA-rated 82-mile range and 119 MPGe. The 2015 Spark EV also keeps its $26,685 (plus destination) starting price from the 2014 model. The car will once again qualify for a federal tax credit of up to $7,500. LG Chem also supplies the cells for GM's other plug-in vehicles from its facility in Western Michigan. The Brownstown production line currently builds the battery packs for the Chevy Volt, the Opel Ampera and the Cadillac ELR. You can read our first drive of the 2014 Chevy Spark here. Brownstown Battery Assembly Expands Capabilities Will build battery system for 2015 Chevrolet Spark EV 2014-05-14 DETROIT – General Motors will bring all its electric vehicle battery building capabilities in-house with production of battery systems for the 2015 Chevrolet Spark EV at its battery assembly plant in Brownstown, Mich. "Using our in-house engineering and manufacturing expertise enabled us to deliver a battery system that is more efficient and lighter than the 2014 Spark EV without sacrificing range," said Larry Nitz, executive director of GM global transmission and electrification engineering. "Our successful working relationship with LG Chem has allowed us to deliver a new battery system for the Spark EV that helps us to better leverage our economies of scale." A newly designed battery system features an overall storage capacity of 19 kWh and uses 192 lithium ion cells. The cells are produced at LG Chem's plant in Holland, Mich. The battery system weight of 474 lbs. is 86 pounds lighter than the system in the 2014 Spark EV. The Spark EV battery is built on a dedicated production line at Brownstown, which also manufactures complete battery packs for the Chevrolet Volt, Opel Ampera and Cadillac ELR.