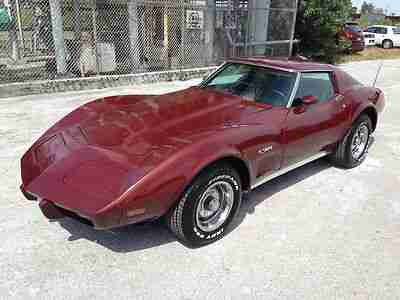

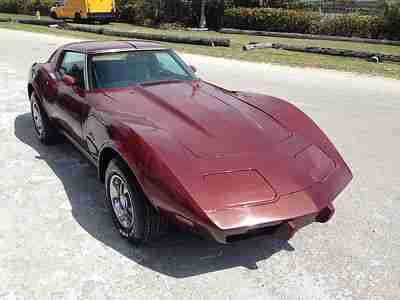

1976 Chevy Corvette Stingray *factory A/c - T Tops - 350/350hp - Super Fast L84 on 2040-cars

Hallandale, Florida, United States

Body Type:Coupe

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Dealer

Make: Chevrolet

Model: Corvette

Mileage: 49,900

Options: CD Player

Sub Model: NO RESERVE

Power Options: Air Conditioning

Exterior Color: Brown

Interior Color: Black

Number of Cylinders: 8

Chevrolet Corvette for Sale

'93 vette, z25 - 40th anniversary, 35k miles, fx3 selective ride, 350/300hp auto

'93 vette, z25 - 40th anniversary, 35k miles, fx3 selective ride, 350/300hp auto Ls1 6 speed clean carfax and clear title well maintain from north carolina

Ls1 6 speed clean carfax and clear title well maintain from north carolina 2013 grand sport 6.2l auto cyber gray metallic

2013 grand sport 6.2l auto cyber gray metallic 63 saddle tan w/saddle interior, 327/360hp fuel injected, 4-speed, pb, pw,fuelie

63 saddle tan w/saddle interior, 327/360hp fuel injected, 4-speed, pb, pw,fuelie 04 commemorative edition z06, 11k miles since new, loaded, 2-owner, clean carfax

04 commemorative edition z06, 11k miles since new, loaded, 2-owner, clean carfax 1989 chevy corvette l98 convertible *83,000 original miles* true "no reserve"

1989 chevy corvette l98 convertible *83,000 original miles* true "no reserve"

Auto Services in Florida

Your Personal Mechanic ★★★★★

Xotic Dream Cars ★★★★★

Wilke`s General Automotive ★★★★★

Whitehead`s Automotive And Radiator Repairs ★★★★★

US Auto Body Shop ★★★★★

United Imports ★★★★★

Auto blog

Domino's reveals Chevy Spark-based delivery car

Wed, Oct 21 2015Next time you order from Domino's Pizza, check out the delivery car. In an effort to get hot and fresh pizzas to hungry customers, the company is creating a small run of custom vehicles that are tailored for the job. Dubbed the Domino's Delivery Expert (DXP), these 2015 Chevrolet Spark-based hatchbacks pack a plethora of features to provide the perfect pie. When the DXP's on delivery duty, every order should arrive steaming hot thanks to the hatchback's biggest custom upgrade – a warming oven right behind the driver. Accessible from outside, it can keep pizzas at the perfect temperature on the way to your house and hold two of Domino's Heatwave bags. Other than the driver's seat, the rest of the interior also gets replaced with bountiful storage and non-slip surfaces. According to the company, as many as 80 pizzas could conceivably fit inside, and that would be quite a party. The exterior is still clearly derived from the Spark but with some clever additions. An illuminated "Out for Delivery" sign is on the roof, and a puddle light shoots the Domino's logo on the ground. Plus, the company's red-and-blue color scheme is emblazoned over the hood, pillars, and hatch. Underneath all the pizza-related mods, power comes from a 1.2-liter four-cylinder and CVT. Rather than just a one-off stunt, Domino's is working with Roush Enterprises and former General Motors exec Kenneth R. Baker to build 100 DXPs. They're hitting the streets in 25 US cities, and you can check if your locale is included on the project's website. The seed of this idea came from a partnership with Local Motors to crowdsource the ultimate pizza delivery platform. Domino's Launches Purpose-Built Pizza Delivery Vehicle Domino's Innovative DXP™ Created by Three Great Michigan Brands and an International Crowdsourcing Design Competition Ann Arbor, Mich., Oct. 21, 2015 -- In its latest innovation as the recognized world leader in pizza delivery, Domino's (NYSE:DPZ) is launching the Domino's DXP™ (Delivery Expert), a specially designed and built pizza delivery vehicle. The DXP is the combined brainchild of former GM R&D executive Kenneth R. Baker, Michigan-based Roush Enterprises and Domino's. To also include consumers' input, hundreds of concepts were initially identified in an online crowdsourcing design competition hosted by Local Motors. "The Domino's DXP is the first purpose-built vehicle aimed at revolutionizing pizza delivery," said Russell Weiner, president of Domino's USA.

2013 Chevy COPO Camaro announced with two new engines and manual option

Thu, 07 Mar 2013Chevrolet is following up the 2012 COPO Camaro with another limited run of the drag-strip-ready production car for 2013. Ditching the superchargers, the 2013 COPO Camaro can only be equipped with one of three naturally aspirated V8 engines, and other new features include the option of a manual transmission, new front springs, some minor styling changes and a lower starting price of $86,000. All cars are designed to abide by the rules of the NHRA's Stock Eliminator or Super Stock classifications, depending on in which series buyers wish to enter their Chevrolet Camaro.

Returning for 2013 is the 427-cubic-inch V8 producing 425 horsepower, but the new engines include a 325-hp 350-CID V8 and a 375-hp 396-CID V8. Buyers can select to purchase all three engines, and each will be matched with the sequence number of that car; the track-only COPO cars will not have vehicle identification numbers and can't be registered for street use.

Chevrolet is also offering unique enthusiast-specific options such as a COPO Build Book and the opportunity for owners to help assemble their car's engine at the Chevrolet Performance Build Center in Wixom, MI.

L.A. Auto Show, Chevy Volt and the Lincoln Navigator | Autoblog Podcast #563

Mon, Dec 3 2018On the latest Autoblog Podcast, Editor-in-Chief Greg Migliore is joined by Green Editor John Snyder. First, they recap the biggest and best reveals of the 2018 Los Angeles Auto Show. Then they take a moment to say goodbye to the Chevy Volt, and to talk about their recent drives in the to-be-discontinued plug-in. Finally, they review the Lincoln Navigator, and marvel at the Black Label's stunning interior treatment.Autoblog Podcast #563 Get The Podcast iTunes – Subscribe to the Autoblog Podcast in iTunes RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Rundown 2018 L.A. Auto Show recap 2020 Porsche 911 2020 Jeep Gladiator 2020 Lincoln Aviator 2019 Mazda3 Rivian R1T pickup and R1S SUV 2020 Hyundai Palisade 2019 Honda Passport Audi E-Tron GT Concept One last drive in the Chevrolet Volt Driving the Lincoln Navigator Feedback Email – Podcast@Autoblog.com Review the show on iTunes Related Video: