1972 Malibu All Original Engine Paint Bucket Seat Car Never Restored No Reserve on 2040-cars

Estacada, OR, United States

Body Type:Coupe

Engine:350 Small Block

Vehicle Title:Clear

Fuel Type:Regular

For Sale By:Private Seller

Interior Color: White and Black

Make: Chevrolet

Number of Cylinders: 8

Model: Chevelle

Trim: 2 Door

Drive Type: Rear Wheel drive

Mileage: 99,000

Exterior Color: Gold

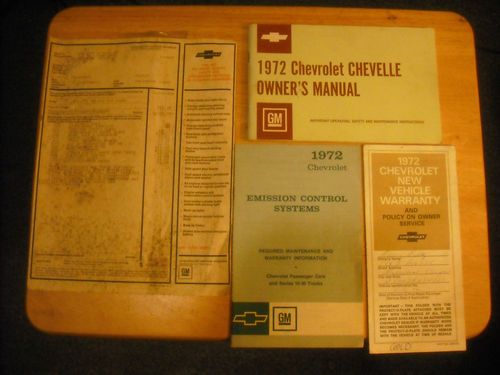

Unrestored Original Chevelle Malibu.Vin Number on engine. Needs complete restoration. Runs and drives but brakes are bad. Car sat for about 10 years would not drive before restoration. Only thing not original is intake and carb. Cowl Tag Reads. 72 13637 R 15369 743 A51 53 A 12B 509 Only about 60,000 were made with bucket seat console combination Dash Has NO CRACKS in it very nice. Trunk and floors are solid Tires and wheels that are on car in pics do not go with car. will put some on for shipping NO RESERVE Also Have Protecto plate, Original Window sticker, Owners manual Clean Title. If you need more pics call 503 333 6771

Chevrolet Chevelle for Sale

70 chevrolet chevelle ss 396 numbers match

70 chevrolet chevelle ss 396 numbers match 1968 chevy chevelle malibu custom protour air ride foose wheels crate engine ss

1968 chevy chevelle malibu custom protour air ride foose wheels crate engine ss 1965 chevelle frame off, bb 4 spd.ac..calif.car no rust privatley owned,must see(US $26,900.00)

1965 chevelle frame off, bb 4 spd.ac..calif.car no rust privatley owned,must see(US $26,900.00) 1967 chevelle super sport 138

1967 chevelle super sport 138 1965 chevelle convertible

1965 chevelle convertible 1964 chevy el camino hot rod(US $15,000.00)

1964 chevy el camino hot rod(US $15,000.00)

Auto Services in Oregon

Zilkoski Auto Electric ★★★★★

Trifer Auto Glass & Window Tint ★★★★★

Stephenson Automotive ★★★★★

Salem Transmission Service ★★★★★

Ricks Quality Import Service ★★★★★

Richmond`s Service ★★★★★

Auto blog

GM recalls Chevy Express, GMC Savana over rollaway concern

Mon, 21 Jan 2013The National Highway Traffic Safety Administration has issued a recall notice for a small number of General Motors fullsize vans due to possible rollaway concerns. On certain 2013 Chevrolet Express and 2013 GMC Savana models, it is possible to remove the key from the ignition without the shifter being in park.

Only 980 total units are being affected by this recall, and GM is fixing the issue by replacing the ignition cylinder and associated keys. Affected Chevy vans were built during most of November and December while its GMC counterpart was only built for a week in November. The recall goes into effect on January 23, and to find out if your vehicle applies to the recall, the GM and NHTSA contact numbers can be found on the official recall notice, which is posted below.

GM's MPG overstatement could affect 2 million vehicles

Tue, May 17 2016Late last week, GM admitted that three of its large SUVs fuel economy window stickers did not match their actual efficiency ratings, and so the vehicles couldn't be sold. The stickers on the 2016 Chevy Traverse, GMC Acadia, and Buick Enclave said their ratings were one to two miles per gallon better than they should have been. Officially, the number of affected vehicles sits at about 60,000. But Consumer Reports makes a good point: what's up with all of the previous model year SUVs that are basically the same vehicle? To wit: the 2016 model year vehicles are not substantially different than the 2015 or the 2014, or even going all the way back to 2007. On the EPA's fuel economy website, all of these older models will "have better stated fuel economy numbers than the new vehicles in GM's dealerships," Consumer Reports noted. CR's best point, and the one that makes the 60,000 number potentially grow to 2 million if all of the vehicles built on this platform are affected, is that "[i]t seems unlikely that the company would change the powertrain on these carryover models so late in their model cycles in a way that would cause a dramatic, negative impact on fuel economy." GM says that earlier model year SUVs are not affected and the EPA did not respond to CR's question about the potential for more discrepancies. We've seen automakers reverse course before, so if GM has to come out with a mea culpa soon, don't be surprised. GM is rushing corrected stickers to dealers so that the SUVs can be sold again, but a fix for the already-sold vehicles could be trickier to solve. Related Video: Related Gallery 2013 GMC Acadia View 16 Photos News Source: Consumer Reports Government/Legal Green Buick Chevrolet GMC Fuel Efficiency mpg gmc acadia chevy traverse

GM shows off 'digital vehicle platform' enabling more in-car tech and OTA updates

Wed, May 22 2019It appears to have dropped the sobriquet "Global B," but General Motors' new electrical architecture has bowed in drawings and video. This is the "digital vehicle platform" GM president Mark Reuss spoke to Reuters about in 2015, saying it would move a great deal of a vehicle's computer work to the cloud and enable over-the-air updates. Reuss took the microphone for the debut, too, saying, "Our new digital vehicle platform and its eventual successors will underpin all our future innovations across a wide range of technological advancements, including EVs and expanded automated driving." The system will go into production later this year, appearing in dealerships first either on the 2020 Cadillac CT5 or the mid-engined 2020 Chevrolet Corvette. Yes, these are the same electronics cited for delaying the launch of the C8 Corvette over excessive draw, security and getting the more-than-100 computer modules to communicate seamlessly. When Car and Driver asked about that, GM replied with "No comment." Volkswagen's having the same issues with the Mk8 Golf right now, though, so GM isn't alone, and this will be the new normal among OEMs for a while. What's certifiable is that the new architecture is robust enough to handle 4.5 terabytes of data per hour, which is five times what GM's current wiring can handle. And thanks to Ethernet connections of 100 Mbps, 1 Gbs and 10 Gbs, communication within and without the vehicle happens much faster. The advances mean better screen resolutions, better battery management for hybrids and electric vehicles, the capability for over-the-air updates and "functionality upgrades throughout the lifespan of the vehicle." Cadillac's Super Cruise has already been lined up as a leading candidate for constant improvements in the driving assistance suite, a key part of GM's "vision for a world with zero crashes, zero emissions and zero congestion." And whenever GM decides to take the plunge, it will mean a 48-volt electrical system. More than 300 specialists worked on the digital platform, and security was a huge part of the task. We've already heard that GM consulted with Boeing and military contractors on how to prevent hacking. The carmaker has an internal Product Cybersecurity group that reached out to the research community, and created a "bug bounty" program to crowdsource uncovering any flaws.