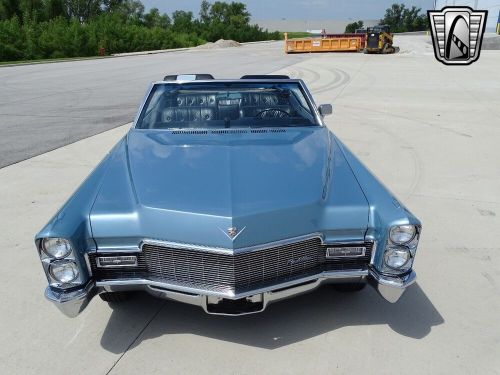

1968 Cadillac Deville on 2040-cars

Engine:472 V8

Fuel Type:Gasoline

Body Type:convertible

Transmission:Automatic

For Sale By:Dealer

VIN (Vehicle Identification Number): 00000000000000000

Mileage: 55164

Make: Cadillac

Drive Type: --

Features: --

Power Options: --

Exterior Color: Blue

Interior Color: Black

Warranty: Vehicle does NOT have an existing warranty

Model: DeVille

Cadillac DeVille for Sale

1950 cadillac deville 1950 cadillac series 62 deluxe coupe devill(US $23,000.00)

1950 cadillac deville 1950 cadillac series 62 deluxe coupe devill(US $23,000.00) 1971 cadillac deville(US $51,500.00)

1971 cadillac deville(US $51,500.00) 1979 cadillac deville(US $1,000.00)

1979 cadillac deville(US $1,000.00) 1969 cadillac deville(US $20,995.00)

1969 cadillac deville(US $20,995.00) 1993 cadillac deville(US $2,550.00)

1993 cadillac deville(US $2,550.00) 1990 cadillac deville v8 low miles classic collector car(US $1,750.00)

1990 cadillac deville v8 low miles classic collector car(US $1,750.00)

Auto blog

Five awesome Lego car creations

Thu, 23 Oct 2014Lego cars are among our favorite toys. They're fun for play, and if built properly, great to display. With that in mind, we've crafted a list of some of the best creations we've seen. Some are on sale now, while others are merely the work of fanciful enthusiasts. There are even a couple that you definitely cannot buy (we'll explain).

Our choices are diverse, including everything from a diminutive 1969 Chevy Corvette to a fullsize Ferrari Formula One racecar. These are just five projects that caught our eye - there are many more out there - so if you don't see your favorite Lego car on the list (or if you have your own creation), please tell us about it, in Comments.

Cadillac tipped to call flagship something other than LTS

Sun, 21 Sep 2014Cadillac wouldn't be Cadillac without large sedans in its lineup, and while the XTS has had to hold down that end of the fort all on its own, it won't have to for too long. That's because the luxury brand in the General Motors portfolio is preparing to roll out its new LTS, stylistically previewed by the Elmiraj concept pictured above. Only now, the latest thinking is that the upcoming flagship model may not be called LTS at all.

As Automotive News points out, Cadillac's naming scheme is all over the place at the moment. The ATS slotting below the CTS makes sense (alphabetically), but where do the ELR, SRX and especially the Escalade fit into that naming hierarchy? And how would LTS - as the project has been known until now - sit above the XTS?

Fortunately, Cadillac may be on the case, as two of the division's most recent senior appointments seem keen to rationalize the naming scheme. One is Uwe Ellinghaus, who joined Cadillac as chief marketing officer late last year. Speaking of the brand's nomenclature last spring, Ellinghaus was quoted as saying, "We are aware that this is currently a weakness of the Cadillac brand." And his new boss is bound to agree.

Why Cadillac is willing to lose 43 percent of its dealers

Sun, Sep 25 2016Cadillac is offering about 400 dealers in the United States a lump sum of money to close down. That represents over 40 percent of Cadillac dealers in America. Offers start at $100,000 and top out at $180,000. The average offering is around $120,000. According to Automotive News, Cadillac chief Johan De Nysschen estimates it will cost the automaker around $50 million to close these dealers. Any dealer that chooses to remain open will have to submit to Cadillac's ambitious Project Pinnacle, which will divide dealers into incentive categories based on how many units they sell. "Every single Cadillac dealer will have the potential to earn significantly higher profits than they do today," says De Nysschen. Dealers have until November 21 to decide if they want to take the cash or submit to Project Pinnacle. A logical question: Why is Cadillac willing to spend $50 million to close down 43 percent of its dealers? First, GM's luxury brand has way more dealerships than it needs. Second, the 400 dealers with offers to shutter each sold 50 or fewer vehicles in 2015, representing just 9 percent of its sales volume in America. So, while closing these smaller dealerships may have a small initial impact on sales, it's not going to be a major hit to Cadillac. Related Video: News Source: Automotive News - sub. req.Image Credit: Gary Cameron / Reuters Cadillac Car Dealers Luxury Performance