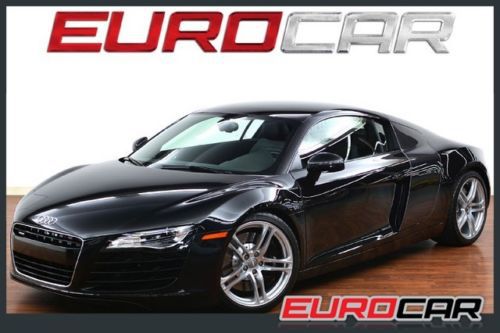

09 Audi R8 Awd R-tronic Bang Olufsen Nav Pdc Cam Carbon 19s Heated Seats 27k on 2040-cars

Stafford, Texas, United States

Audi R8 for Sale

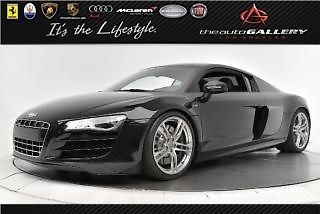

12 audi r8 quattro awd 5.2l v10 manual 10k bang olufsen nav pdc rear cam carbon(US $129,995.00)

12 audi r8 quattro awd 5.2l v10 manual 10k bang olufsen nav pdc rear cam carbon(US $129,995.00) Audi r8,(US $111,777.00)

Audi r8,(US $111,777.00) 2010 audi r8 2dr cpe auto quattro 5.2l security system air conditioning

2010 audi r8 2dr cpe auto quattro 5.2l security system air conditioning Rare red v10 carbon r8 r-tronic only 4k miles 3m clear bra attention galore! gt(US $125,000.00)

Rare red v10 carbon r8 r-tronic only 4k miles 3m clear bra attention galore! gt(US $125,000.00) (C $85,000.00)

(C $85,000.00) 2011 audi r8 5.2 quattro spyder cabriolet awd nav 11k texas direct auto(US $127,980.00)

2011 audi r8 5.2 quattro spyder cabriolet awd nav 11k texas direct auto(US $127,980.00)

Auto Services in Texas

Z Rated Automotive Sales & Service ★★★★★

Xtreme Tinting & Alarms ★★★★★

Wayne`s World of Cars ★★★★★

Vaughan`s Auto Glass ★★★★★

Vandergriff Honda ★★★★★

Trade Lane Motors ★★★★★

Auto blog

Audi A3 E-Tron Sportback already getting residual value love

Fri, Feb 6 2015It's a tricky game, but the folks at Auto Bild and market research institute Schwacke are looking into the future. Through the mists of future time, they say that they think that buying an Audi A3 Sportback e-tron plug-in hybrid today is going to look like a smart buy in a few years. The German automaker likes what it sees in terms of resale value for the plug-in hybrid A3, Audi's first mass-produced plug-in, and the car has already been named a "Wertmeister." That's the "value champ" designation that Auto Bild hands out every year. Audi says the A3 e-tron has the "most stable residual value in its class," and is expected to retain more than 57 percent of its original value four years after rolling off the dealership lot. That gives the plug-in hybrid bragging rights to the "Wertmeister" award for the Compact Car category. Audi also won second place in the Full Size category with its Audi A6 Avant 3.0 TDI The German automaker started sales of the A3 e-tron last summer in Germany, pricing the model at about $51,500. The cars has 204 horsepower, can go from 0 to 60 miles per hour in less than eight seconds and has an all-electric range of up to 31 miles. Check out Audi's press release below, and take a look at our First Drive impressions of the model here. Audi A3 Sportback e-tron is "Wertmeister 2015" Auto Bild crowns Audi A3 Sportback e-tron "Wertmeister 2015" Audi A6, Audi A7 and Audi Q3 also awarded top-three places Ingolstadt/Berlin, February 5, 2015 – the Audi A3 Sportback e-tron* is the car with the most stable residual value in its class. That was the conclusion drawn by Auto Bild and market research institute Schwacke. The A3 e-tron stands out with the best residual value forecast among the compact cars, receiving the title "Wertmeister 2015". Every year, Auto Bild and Schwacke select the cars in each class that are expected to depreciate the least during the following four years. The winners take the "Wertmeister" title. The Audi A3 Sportback e-tron is the winner in the "Compact Car" category with a residual value of 57.3 percent. The Audi A3 e-tron is the first plug-in hybrid from Audi. It combines sporty power with impressive efficiency and abundant driving enjoyment with unrestricted everyday utility.

A fix is finally coming for some diesel Volkswagens in America

Fri, Jan 6 2017According to Automotive News, the EPA has approved a fix for select Volkswagen and Audi 2.0-liter diesel vehicles. The fix applies to 2015 VW Beetles, Golfs, Golf SportWagens, Jettas, Passats, and Audi A3s. Unfortunately for a majority of people saddled with cheating VWs, Automotive News reports that only about 70,000 vehicles will get this fix. The remainder of the 475,000 affected cars don't have an approved fix yet. The fix first involves a software update. Later, a particulate filter and additional catalysts will be installed with a further software update. According to Automotive News, the hardware portion will be available next year. Despite the small number of vehicles approved, this may give VW owners some hope that they'll be able to make their cars emissions compliant. Volkswagen also recently got approval for a fix of nine million cars in Europe, and the company may be close to a fix for diesel V6 models. However, for owners of 2.0-liter models uninterested in waiting for a fix, they can still participate in the buyback. Volkswagen would prefer that repurchased cars aren't stripped of parts beforehand, though. Related Video: Featured Gallery 2015 Volkswagen Jetta TDI: Review View 42 Photos News Source: Automotive NewsImage Credit: Seyth Miersma Green Audi Volkswagen Emissions Diesel Vehicles vw diesel scandal

Leaked Audi product roadmap may confirm R8 with V6 engine

Tue, Feb 23 2016About a year ago, we reported that Audi was considering downsized engines for the new R8, which launched in V10 form. This is partially due to the Chinese market's desire for smaller displacement engines, and partially due to R8 technical lead Roland Schala's statement that a "V6 is a perfect engine for this car." This leaked upcoming product schedule, passed on by our friends at Autobahn.eu, seems to confirm these rumors. Based on the information in the image above, the R8 V6 is due in 2018. The rest of the product map seems to square with vehicles we know are in the pipeline. We spied the SQ7, A5, and R8 Spyder about a year ago, and the TT RS a few months ago. We told you in December a new Q5 is on the way, too. We just heard a credible rumor that the RS3 is on the way in 2017 as a 2018 model, and may even come to America, which squares with what we're seeing here. And we drove the Q7 E-Tron in 2015 – it's going on sale in Europe soon. This graphic puts the on-sale date as October 2017; that could be for the US market. Puzzlingly, this graphic doesn't discuss the Q2, which Audi just teased today. We're not sure what to make of that. Now onto the fun stuff. 2018 should be when Audi reveals a new A8 (featuring, most likely, a version of the futuristic Virtual Dashboard seen at CES) and A7, an RS 5 Coupe launching a few months after the A5/S5, a new A6, and the already-confirmed Q8 SUV. All expected or already confirmed. What about the cryptically-named "C-BEV?" If we extrapolate that to mean C-segment EV, if could be the Audi version of the stand-alone EV that VW is reportedly developing, and no, it's not the next E-Golf. We expected this MEB-based vehicle to debut in 2018, before the next-generation Golf, so again our rumors square nicely with what this roadmap tells us. Let's leave it at this: if you're an Audi fan, the next few years are going to be quite exciting. Expect some of these rumors to be confirmed in Geneva, so keep your eyes here for more Audi and VW info. Related Video: