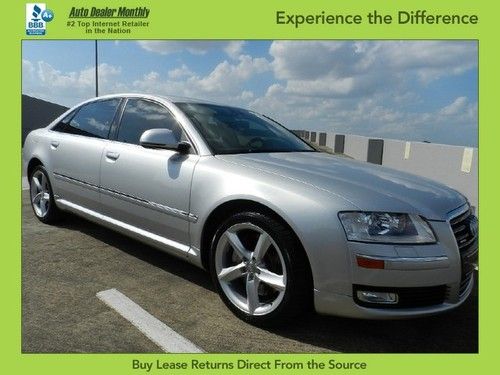

2007 Audi A8l on 2040-cars

Oakville, Ontario, Canada

Body Type:Sedan

Vehicle Title:Clear

Engine:4.2L

Number of Cylinders: 8

Make: Audi

Model: A8

Trim: L

Options: Sunroof, 4-Wheel Drive, Leather Seats, CD Player

Drive Type: Quattro

Safety Features: Anti-Lock Brakes, Driver Airbag, Passenger Airbag, Side Airbags

Mileage: 107,000

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Exterior Color: Blue

Warranty: Vehicle has an existing warranty

Interior Color: Black

Up For Auction....

2007 Audi A8L finished in Northern Lights Blue on Charcoal full leather with Alcantara Package.

Car is fully optioned with.....4 zone A/C and Heat....backup camera....Navigation....Sirius radio....Heated and Cooled seats with massage....Very Rare Rear Seat Lumbar....Adaptive Cruise control....Side and rear sun shades,and the list goes on, and on. This beautiful car rides like a dream and gets great fuel economy. I had brand new tires done in February 2013 plus a 4 wheel alignment done at that time as well.

Car does have 14 months of Warranty remaining. All maintenance is up to date and just had the oil changed.

I am only selling because I just retired and also have a '05 Navigator (Navigator pulls my classic car to shows) and I no longer need two big vehicles.

$500 deposit required at end of auction, balance due in 7 days, cash in person or wire transfer or certified cheque....money needs to clear before car goes. I can help with shipping if needed but at your cost.

Audi A8 for Sale

2012 audi a8 l - quattro tiptronic sedan 4-door 4.2l--premium package(US $77,500.00)

2012 audi a8 l - quattro tiptronic sedan 4-door 4.2l--premium package(US $77,500.00) 2005 audi a8l w12 quattro rare pearl white dvd long wheel base

2005 audi a8l w12 quattro rare pearl white dvd long wheel base 2011 a8l quattro awd led premium pano loaded 20" wheels low reserve look

2011 a8l quattro awd led premium pano loaded 20" wheels low reserve look Warranty navigation reverse cam moonroof one owner non smoker clean carfax(US $39,400.00)

Warranty navigation reverse cam moonroof one owner non smoker clean carfax(US $39,400.00) Certified audi a8 l

Certified audi a8 l 2004 audi a8 quattro l sedan 4-door 4.2l(US $15,499.00)

2004 audi a8 quattro l sedan 4-door 4.2l(US $15,499.00)

Auto blog

Audi recalls 850,000 A4 models globally for airbags that won't deploy

Thu, 23 Oct 2014Audi has announced that it will be recalling 850,000 A4 sedans, wagons and Allroad models across the globe due to a software problem that could prevent the front airbags from deploying. All 850,000 vehicles were built after 2012.

Audi has already adjusted production of new A4s to eliminate the software glitch. Meanwhile, the German manufacturer was quick to emphasize that Takata did not manufacture the affected airbags.

According to Reuters, 250,000 of the affected A4s were built for the Chinese market, while another 150,000 were sold in Germany. Audi didn't provide a breakdown beyond those two countries, although it'd be a surprise if there weren't at least some affected airbags in the US market.

VW internal investigation finds 'no evidence' against suspended engineers

Tue, Oct 6 2015Volkswagen is still working out the chain of events that led to emissions-evading software being installed in 11 million diesel vehicles worldwide and deciding who was responsible for the treachery. So far, the German automotive giant's internal investigation hasn't publicly named many suspects, and three suspended executive-level engineers have been found not to be culpable in the wrongdoing, according to an anonymous insider speaking to Reuters. VW knows that the software began being installed in the EA 189 engine in 2008. The internal investigation has found that the emissions-evading tech was created because the powerplant was found to fail US standards. Plus, the diesel mill wasn't meeting cost targets, according to Reuters. The automaker responded by suspending over 10 employees, but three top engineers among them might not have been involved. Those put on leave include Heinz-Jakob Neusser from VW, Ulrich Hackenberg from Audi, and Wolfgang Hatz who led Porsche's research and group-wide engine development. The internal detective work hasn't turned up any evidence against these three men. In addition to VW's own inquires, government investigators in both the US and Germany are taking a serious look into the company's actions, too. So far, the automaker is setting aside about $7.3 billion to pay to fix the vehicles with the evasive software. Depending on what authorities find, the costs could grow quickly. Beyond the financial implications, the scandal has led to a serious shakeup in VW's corporate structure. Related Video:

2016 Audi TTS

Wed, 08 Oct 2014We recently drove the Audi TT, and although we wish it were radically entertaining instead of merely very fun, it's nevertheless a sharp coupe that vaults ahead of its predecessor with an inspired interior and eager handling. That car will be precursor to this TTS when it gets here a year from now, with the TTS adding adjectives like "more" and "better" to just about everything found on the base coupe. With the standard car having already put on such a fine edge, we wheeled the TTS on Spanish roads and at the Ascari race track to find out how much better and higher-performing the S will be.

Driving Notes

As of this writing, today's TTS commands an $8,350 premium over the TT. Assuming a commensurate gap is carried over into this next generation model, that supplemental dosh will get you 310 horsepower and 280 pound-feet of torque instead of 230 hp and 273 lb-ft in the standard TT. That would mean more for your money, too, since the gap between the current TT and TTS is 54 hp and zero lb-ft of torque. To achieve the new numbers, the 2.0 TSFI engine from the TTS benefits from upgrades like sturdier valves, revised aluminum pistons and stronger connecting rods with new bearings, a reinforced crankshaft and a high-performance intercooler. The amplified brawn rips 0.7 seconds off the 0-60 mile-per-hour time, getting you there in 4.6 seconds.