Audi A6 for Sale

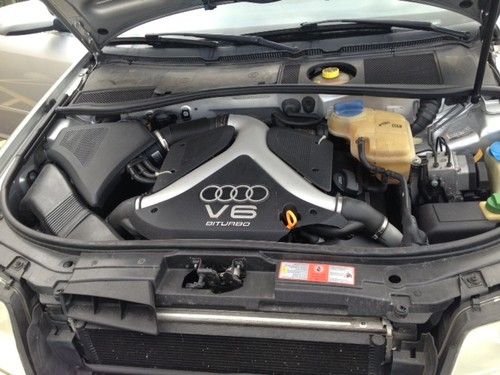

2000 audi a6 quattro base sedan 4-door 4.2l(US $5,000.00)

2000 audi a6 quattro base sedan 4-door 4.2l(US $5,000.00) 2012 audi a6 3.0 tfsi quattro tiptronic - fully loaded / like new condition(US $49,000.00)

2012 audi a6 3.0 tfsi quattro tiptronic - fully loaded / like new condition(US $49,000.00) 2010 audi a6 quattro base sedan 4-door 3.0l(US $45,000.00)

2010 audi a6 quattro base sedan 4-door 3.0l(US $45,000.00) 2005 audi a6 quattro sedan 4-door 3.2l(US $6,500.00)

2005 audi a6 quattro sedan 4-door 3.2l(US $6,500.00) 2000 audi a6 quattro base sedan 4-door 2.8l

2000 audi a6 quattro base sedan 4-door 2.8l

Auto blog

VW, Mobileye to bring new automated tech to series production

Wed, Mar 20 2024Volkswagen will bring new automated driving technologies to series production as it deepens its partnership with Mobileye in automotive driving technologies, Europe's biggest carmaker said on Wednesday. Israeli automotive tech company Mobileye will provide driving assistance software based on its SuperVision and Chauffeur platforms to VW's luxury brands such as Audi, Bentley, Lamborghini and Porsche. The technologies, which later will be integrated by VW's software unit Cariad, include assistance systems for highway and urban driving, such as automated overtaking on multilane highways, automatic stopping at red lights and stop signs, and support in intersections and roundabouts. "New automated driving functions will significantly boost convenience and safety," VW Chief Executive Oliver Blume said. Mobileye is also set to supply further automated driving software to Volkswagen's commercial vehicles unit. In future, the German carmaker aims to rely on its own complete in-house software system. (Reporting by Christoph Steitz, writing by Andrey Sychev, Editing by Miranda Murray and Madeline Chambers)

VW reaches out to diesel consumers with new website

Tue, Sep 29 2015Volkswagen is starting to get details out to the public about its diesel emissions evasions in the US, and the automaker now has a dedicated website for consumers. The first thing that visitors see is an apology video from Volkswagen Group of America CEO Michael Horn. The site also details all of the VW TDI's currently known to be affected here, including the 2009-2015 Jetta, 2009-2014 Jetta SportWagen, 2010-2015 Golf, 2015 Golf SportWagen, 2012-2015 Beetle and Beetle convertible, and 2012-2015 Passat. Although, the Audi A3 should be on there, too. The company repeatedly reassures owners that these vehicles are safe to drive and promises it's developing a fix as quickly as possible to make them emissions compliant. On the site's FAQ, VW also clarifies that there's still a stop-sale on all of these models with the 2.0-liter TDI, including certified pre-owned ones. That could change soon because the automaker believes that the 2016 model year examples are legal, but the Environmental Protection Agency needs to sign off before they could go to dealers. Until the diesels can be sold, there also won't be any TDI advertising by VW. "We are working at full speed on a technical solution that we will present to partners, to our customers and to the public as swiftly as possible," Herbert Diess, CEO of Volkswagen passenger car division, says in a statement. He also offers an improved accounting of the number of vehicles affected. VW had previously said that there were 11 million with the emissions evading software worldwide. According to Diess, around five million of these came from the VW brand. Audi has said there about 2.1 million of its models affected globally with between 13,000 and 14,000 in America. DR. HERBERT DIESS, CEO OF THE VOLKSWAGEN PASSENGER CARS BRAND, EXPLAINS: "WE ARE WORKING AT FULL SPEED ON A SOLUTION." Wolfsburg, September 25, 2015 – In the press release dated September 22, 2015, the Volkswagen Group announced that Volkswagen Group vehicles worldwide are affected by the current issues regarding emissions. The internal evaluation revealed that approximately five million Volkswagen Passenger Cars brand vehicles are affected worldwide. Certain models and model years of these vehicles (such as the sixth generation Volkswagen Golf, the seventh generation Volkswagen Passat and the first generation Volkswagen Tiguan) are equipped exclusively with type EA 189 diesel engines.

Ford GT, Buick Avenir and Audi Q7 take 2015 EyesOn Design awards

Thu, Jan 15 2015The annual EyesOn Design Awards at the Detroit Auto Show allows some of the greatest designers in the world to weigh in on the best production and concept debuts at the big event each year. For 2015, the large panel of judges included luminaries like Frank Stephenson of McLaren, Ralph Gilles from FCA and Moray Callum of Ford. Apparently the editors at Autoblog had a good eye because the winner of 2015's Best Designed Production Vehicle award went to the Ford GT, which was also our favorite debut from the show. The new supercar beat the Acura NSX and Mercedes-Benz GLE-Class Coupe for the honor. The judges described the Blue Oval's shape as "capturing the original GT40 in a modern interpretation," according to EyesOn Design. The Buick Avenir was also a big winner in the awards this year and received the nods for both Best Designed Concept Vehicle and Innovative Use of Color, Graphics and Materials. In the concept category, it beat out the Chevrolet Bolt and Mercedes-Benz F 015, and in the latter group, the sedan triumphed over Audi Q7, Mercedes F 015 and Volkswagen Cross Coupe GTE. The Q7 received its own accolade for Best Designed Interior, and it beat the Avenir and Infiniti Q60 for the honor. This year's Lifetime Design Achievement Award went to former Renault designer Patrick le Quement, and Bob Lutz received the EyesOn Design Catalyst Award for the second time. The honor is for an executive "who has empowered great design," according to the organization, which describes Lutz perfectly. Scroll down to read the announcement with more comments about the winners. Related Video: Ford, Buick, Audi recipients of EyesOn Design Awards at North American International Auto Show EyesOn Design Awards for Design Excellence for 2015 were revealed today at the North American International Auto Show. The awards honor the most significant automotive designs revealed at NAIAS as determined by the North American and global leaders of design from automotive manufacturers, along with academic chairs of transportation design programs and design leaders from other fields.