1999 Chevrolet K3500 4x4 Ls Crew Cab Pickup 4-door 6.5l on 2040-cars

Sarona, Wisconsin, United States

|

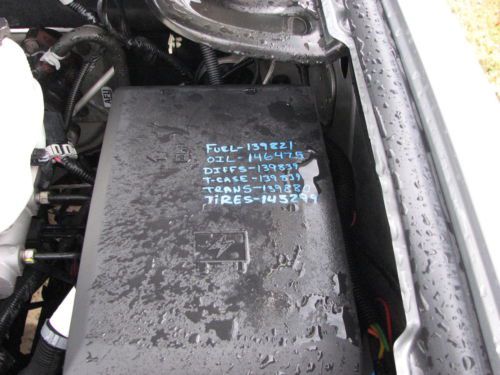

This truck has been stored in the winter and is rust free. The front end was rebuilt at 195,000 miles and the transmission was updated at that time also. I have sold the camper and no longer need the truck. Bench seats front and rear. The truck runs and drives great! |

Chevrolet C/K Pickup 3500 for Sale

1996 used 5.7l v8 16v rwd

1996 used 5.7l v8 16v rwd 2008 chevrolet 3500 crew cab 4wd diesel hauler or ramp truck(US $39,999.99)

2008 chevrolet 3500 crew cab 4wd diesel hauler or ramp truck(US $39,999.99) 2000 chevrolet 3500 at&t service utility fleet work splicer truck only 56k miles(US $6,200.00)

2000 chevrolet 3500 at&t service utility fleet work splicer truck only 56k miles(US $6,200.00) 1993 chevy gmc 4x4 custom duramax conversion swap lly allsion diesel silverado

1993 chevy gmc 4x4 custom duramax conversion swap lly allsion diesel silverado 1971 chevy one ton dually

1971 chevy one ton dually Chevrolet c30 bonanza 1979 454

Chevrolet c30 bonanza 1979 454

Auto Services in Wisconsin

Versus Paint & Collision ★★★★★

U S Speed Research ★★★★★

Topel`s Towing & Repair Inc ★★★★★

Tj`s Auto Body ★★★★★

Swant Graber Ford ★★★★★

Sebring Garage ★★★★★

Auto blog

Best and Worst GM Cars

Thu, Apr 7 2022Oh yes, because we just love receiving angry letters from devoted Pontiac Grand Am enthusiasts, we have decided to go there. Based on a heated group Slack conversation, the topic came up about the best and worst GM cars. First of all time, and then those currently on sale, and then just mostly a rambling discussion of Oldsmobiles our parents and grandparents owned (or engineered). Eventually, three of us made the video above. Like it? Maybe we can make more. Many awesome GM cars are definitely going unmentioned here, so please let us know your bests and worsts in the comments below. Mostly, it's important to note that this post largely exists as a vehicle for delivering the above video that dives far deeper into GM's greatest hits and biggest flops, specifically those from the 1980s and 1990s. What you'll find below is a collection of our editors identifying a best current and best-of-all-time choice, plus a worst current and worst-of-all-time choice. Comprehensive it is not, but again, comments. -Senior Editor James Riswick Best Current GM Vehicle Chevrolet Corvette We were flying by the seats of our pants a bit in this first outing and my notes were similarly extemporaneous. When it came time to tie it all together on camera, I failed spectacularly. Thank the maker for text, because this gives me the opportunity to perhaps slightly better explain my convoluted reasoning. I chose the C8 Corvette because it's simply overwhelmingly good, and it's merely the baseline from which this generation of Corvette will be expanded. While the Cadillac CT5-V Blackwing (more on that in a minute) is an amazing snapshot of GM's current performance standing and its little sibling so enraptured me that I went out and bought one, their existence is fleeting. Corvette will live on; forced-induction Cadillac sport sedans, not so much. So while all three are amazing machines when viewed in a vacuum, the Corvette stands above them as both a reflection of GM's current performance credentials and a signpost of what is to come. So, given the choice between the C8 and the 5V-Blackwing right now, I'd choose the C8. In 10 years, when the Blackwing is no longer in production and Corvette is in its 9th generation? Well, that might be a different story. Now, just pretend I said something even remotely that coherent when we get to the part of the video where I try to make an argument for the 5-V Blackwing as best GM car I've ever driven. Or just laugh at me while I ramble incoherently.

Pure Vision Design TT Camaro has 1,400 reasons to want it

Wed, 06 Nov 2013We've talked about Pure Vision Design before, a California-based company that made waves at last year's SEMA show with its Martini-liveried, Indy-car-powered Ford Mustang. That same car later starred in a Petrolicious video we showed you just a few weeks back. The company's latest creation is a menacing car it calls the Pure Vision Design TT Camaro. Based on a 1972 model, this car shares the Martini Mustang's clean styling and obsession with details.

Unlike the Mustang, which draws its power from a mid-60s Lotus-Ford Indycar engine, the "TT" in this Camaro's name implies something far more potent. The Nelson Racing Engines 427-cubic-inch V8 has been fitted with a pair of turbochargers, with a claimed output of 1,400 horsepower. That's almost 1,000 more than the Martini Mustang.

A six-speed Magnum transmission dispatches that power to the ground, while Pirelli PZero tires are tasked with (somehow) trying to grip the road. Baer brakes hide behind those HRE rims, while JRI coilovers and HyperTech springs bless the Camaro with some degree of competency in the bends.

Chevy donates first 2016 COPO Camaro to United Way

Fri, Jan 29 2016Want to get your hands on the first new COPO Camaro? Scottsdale will be the place to be this weekend. That's where Barrett-Jackson will auction off the drag-racing muscle car with the serial number 2016COPO001. The example on the docket is the very same show car that Chevy revealed at the SEMA show just a couple of months ago. Like every new COPO Camaro, it's based on the new sixth-generation coupe and packs an array of drag-racing upgrades. Those include a three-speed automatic transmission, solid rear axle, and adjustable suspension. While Chevy will offer the new COPO Camaro with a choice of three engines, this particular example packs the 5.7-liter supercharged V8, as well as a unique red and black livery designed by Chevy drag racing driver Courtney Force. 100 percent of the proceeds from the sale are destined to go to United Way, following previous examples that benefited wounded veterans. You can bet it will raise a pretty penny at auction, but if you miss this one, of course there will be more. Just don't wait around too long as the Bowtie brand will only make 69 of them this year. 2016 COPO Camaro No. 1 Sale to Benefit United Way Courtney Force designed show car to be auctioned for United Way 2016-01-26 DETROIT – Chevrolet will auction off the first, sixth generation 2016 COPO Camaro race car to raise money for United Way. The purpose-built COPO Camaro, serial number 2016COPO001, will be sold on Friday, Jan. 29, at the Barrett-Jackson Scottsdale auction. All proceeds of the winning bid will benefit United Way. "This is a special opportunity to purchase the first of the sixth generation, 2016 COPO Camaro while also helping such a great cause," said Jim Campbell, U.S. vice president of Performance Vehicles and Motorsports. The COPO is a powerful, purpose-built Camaro designed to race in NHRA Stock Eliminator class. The COPO Camaro legacy continues with an all-new sixth-generation version. This modern-looking machine infuses legendary COPO performance with the modern, lighter and stronger design of the 2016 Camaro. Chevrolet introduced the sixth generation COPO Camaro No. 001 last November at the SEMA Show and includes a personalized look created by Chevrolet and NHRA Funny Car driver Courtney Force. It features a Red Hot exterior color with Courtney Force-signature graphics and red-accented grille trim. "I was extremely honored to work with Chevrolet and help design the 2016 COPO Camaro," said Courtney Force.